why short the leads of a piezo together for shipping ?

I always try to twist the bare leads of a piezo together before mailing a kit, especially if the piezo is put in the same bag as the rest of the kit.

|

| bare leads twisted together (left side) |

Why ? As seen here a piezo sounder is not only a speaker but can also function as a microphone:

|

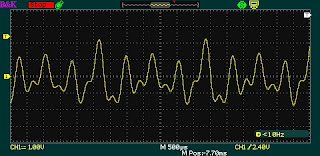

| waveform of me yelling into a piezo |

And as seen here, if a piezo is rapped on a bench top it'll generate a substantial voltage of over 20 volts - don't want that applied to static sensitive parts.

|

| waveform of piezo brought down hard on bench |

AND, the piezo is a highly capacitive part, seen here measuring 63 nF (or .063 uF)

|

| the piezo measured at 63 nF |

, we don't want whatever charge is stored on that capacitor to be discharged into the other kit parts.

Is shorting the leads together effective ? I dunno, but most mechanical meter movements are stored/shipped with their terminals shorted together (also some VOMs have an off position that does the shorting), I figure it can't hurt to do the same with a piezo that will be subject to normal shipment handling.

Why did this become a habit ? As I recall I just noticed a click after shorting the leads of an unconnected piezo together, that click had to come from some current flow.

Does this have implications for portable equipment with a piezo in it ? Not sure, the usual dodge is that once in a circuit the MOS devices have all inputs/ground/power connected so any static charge will be able to flow via protection circuitry and not harm the part, who really knows ? :)

Best Regards,

Chuck, WB9KZY

http://wb9kzy.com/ham.htm